It’s a universal truth in construction: the highest fills, heaviest loads, or tallest structures always seem to land on the weakest soils. These are the sites where traditional ground improvement techniques like stone columns or soil mixing often hit their limits. When soils are extremely soft—think toothpaste consistency—many methods are either difficult to construct or simply won’t deliver the performance needed.

That’s where Rigid Inclusions (RI) come in.

What Are Rigid Inclusions?

Rigid Inclusions are a column-style ground improvement method designed specifically for weak and compressible soils. While stone columns rely on surrounding soils for confinement, RIs use a stiff material (most commonly grout) that maintains its shape even in the weakest soils.

Other materials can also be used, including:

- Precast concrete piles

- Timber piles

- Pipe piles

But grout-based RIs remain the most widely applied in today’s projects due to their adaptability and performance.

How Rigid Inclusions Work

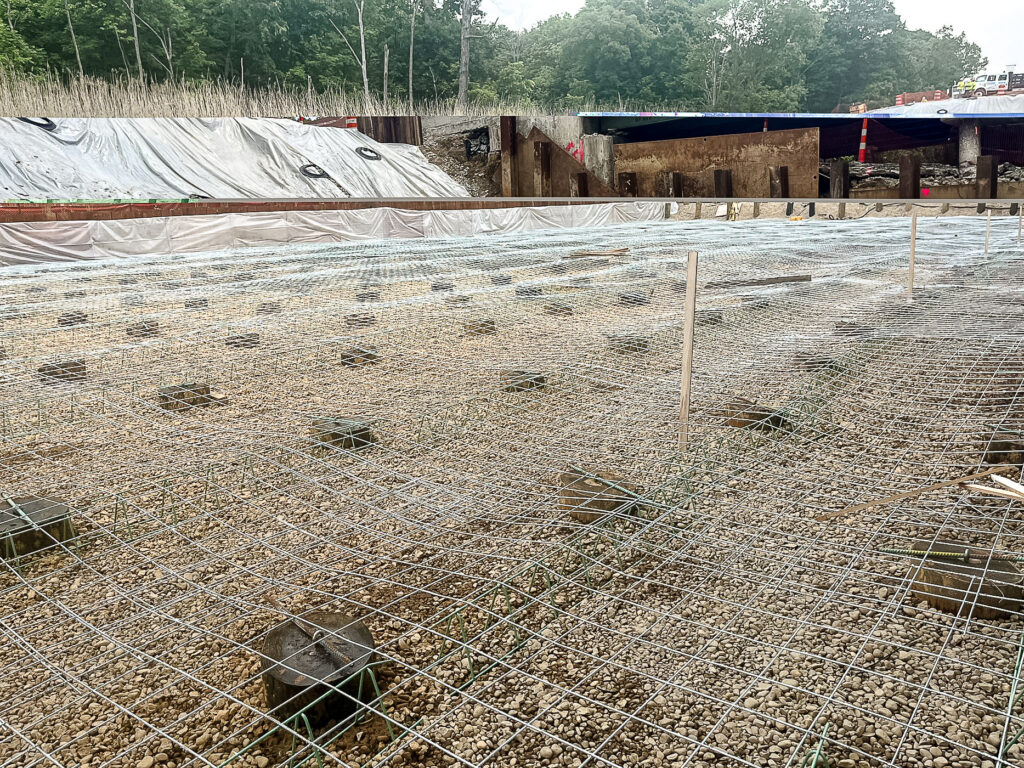

Rigid Inclusions don’t connect directly to the structure above. Instead, loads are transferred through a Load Transfer Platform (LTP)—a compacted granular layer that distributes structural loads evenly across the RI elements.

The LTP can be configured in two primary ways:

- Continuous Platforms – under slabs or large area loads

- Discrete Bearing Pads – placed beneath individual footings

Geosynthetic reinforcement is sometimes included in the LTP, but in many building applications with tight settlement tolerances, there is too little movement for reinforcement to meaningfully engage.

The Role of Design and Installation

There are many design approaches and installation techniques for RIs, and experience is critical. Finite Element Modeling (FEM) is typically used to estimate settlement at the LTP level and stresses within the RI elements. However, a model is only as reliable as the judgment of the engineer interpreting it and the skill of the installer in the field.

For grout-based RIs, proper mix design is vital. The grout must have low slump to hold shape in soft soils. Diluting the mix to ease pumping is a classic mistake that can compromise the entire system—an error experienced teams know to avoid.

Why Choose Rigid Inclusions?

When designed and installed correctly, RIs are:

- Cost-effective – allowing the use of standard shallow foundations instead of deep piles

- Versatile – suitable for soft soils like fibrous peat or fat clay

- Reliable – proven to perform even in the most challenging subsurface conditions

Rigid Inclusions give owners and builders confidence that their structures will remain serviceable and settlements will be controlled—without resorting to the cost of deep foundations.

Garbin GeoStructural Group’s Expertise

At Garbin GeoStructural Group (GGG), we specialize in designing and implementing innovative ground improvement systems tailored to each site’s unique soil conditions. Led by Dr. Ed Garbin, a nationally recognized expert in rigid inclusions, stone columns, and advanced geostructural solutions, our team has helped contractors and owners across the U.S. build safely and economically on soils once thought “unbuildable.”

If you’re facing a project with soft, compressible, or organic soils, contact us today at Garbin GeoStructural Group and ask us about Rigid Inclusions. Our expertise ensures your project stays on budget, on schedule, and on solid ground.